Being the leading brand of Umeshu with a history of more than 100 years, CHOYA is the first company commercializing and selling Umeshu. Exports to more than 80 countries, and also having the biggest market share in Japan.

From Tree to Table

__________

The beginning of summer brings the rainy season, which leads ume fruits to grow and ripe. This is the time when the ume starts its time-consuming,

yet important journey to becoming a delicious CHOYA Umeshu.

|

Step 1. HARVESTING

CHOYA uses only Japan-grown ume fruit. Moreover, we mostly use the premium Nanko species from the Kishu region in Wakayama. This ume is large in size, with thick flesh and high in organic acids. Carefully picking each fruit at its peak right before it falls from the tree allows us to choose only the best suitable ume for Umeshu making. |

|

Step 2. STEEPING

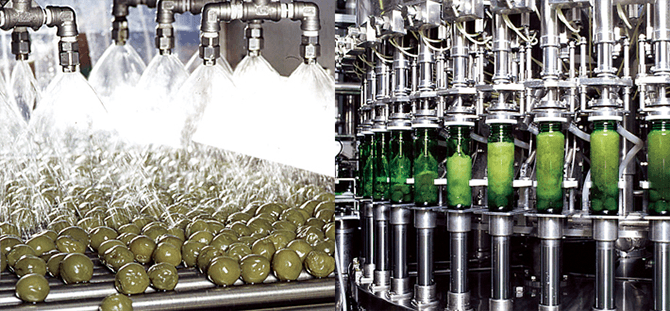

Freshly picked ume fruit are brought to the factory where they are washed and later steeped in a dedicated aging tank, with a capacity up to 100kL, together with alcohol and sugar. We follow a simple yet sophisticated method - a traditional way of making Umeshu without adding unnecessary things or procedures. In total, we have about 450 ageing tanks that are separated by the type of ume, its region and its maturity.

|

|

Step 3. AGEING Our Umeshu storage tanks are specially designed in order to protect against external influences such as light, temperature, and air. This allows us to age the ume liqueur carefully and deliberately for about a year fully extracting ume components through a process we call “Still Ageing” (Independent Ageing). |

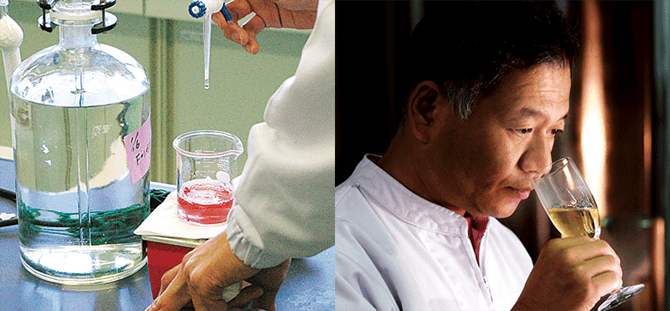

Step 4. BLENDING |  |

Our master blenders analyze various qualities of each Umeshu batch including the taste and aroma. Only those blends that pass rigorous testing are used for making CHOYA products. Not containing any artificial additives, each batch of pure Umeshu has different characteristics. Through pioneering blending techniques that were developed over a hundred years, we are able to deliver consistently high quality and delicious Umeshu. | |

| Step 5: BOTTLING |

Only Umeshu that meets strict CHOYA standards is bottled, inspected, and packaged. For ume containing products, every single fruit is checked by skilled hands, then washed and placed inside bottles. Before packaging, we take great care by visually inspecting final products for any abnormalities. | |